OWP

Metal Bell Xylophone Instrument- Fair Trade- India

Metal Bell Xylophone Instrument- Fair Trade- India

Couldn't load pickup availability

A traditional xylophone, with origins in Africa and Asia, consists of wooden bars of varying lengths with each bar tuned to a specific musical scale. This interesting variation contains bells in various sizes mounted on a wooden board that sits on a flat surface to play. The bells differ in size and scale so each of them will produce a different sound when they are hit with the wooden mallet.

This xylophone, made mostly from recycled scrap metal, is handcrafted by metal artisans at a Noah's Ark workshop in Moradabad, India. Moradabad is one of the largest metal-producing cities in India, well known for its high-quality metal craftsmanship.

- Measures 6” high x 26-1/2” wide x 7-1/2” deep

- The wooden mallet is 8-3/4” long

Handmade in India and fair trade imported.

Hailing from the Western Indian towns of Kutch and Gujarat, these metal bells were traditionally made for cattle, with different sizes and tones to help herders identify their animals. The artisans, descendants of the Lohar caste which originated in Pakistan, have been making bells for as far back as they can trace their ancestry. These days, bells are made using iron scraps that are salvaged from junkyards and then hand-pressed into a variety of shapes and sizes, just as they have been for the past 1,000 years.

After achieving their shape, the bells are covered with powdered copper and mud paste and then baked in a furnace for a rustic finish. The entire process generates a minimal amount of waste, just small traces of metal scrap and burnt mud, and because they’re not welded, a very small amount of energy

About the Artisans:

This item was handmade in India in a workshop sponsored by Noah’s Ark, an NGO that offers funding for raw materials, machines, and workshop repairs to 100 artisan groups across India. In exchange for assistance, workshops must prove that all employees are paid fair wages for their products and work in safe and clean conditions. Noah's Ark also offers free classes in capacity building to its network of 600 artisans, a rigorous quality control check, and runs education and water sanitation projects to benefit the artisans’ children and the rest of the community. The company has established 20 new workshops in the past 15 years, and all employees are paid 10-15% above the local rate.

To learn more, click on "About the Artisans" below.

Share

About the Artisans

About the Artisans

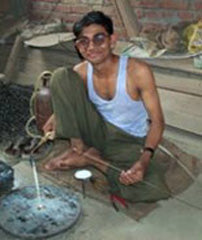

Kamrool Hassan is a metal artisan from Moradabad, a city located in northern India. He has been associated with Noah's Ark for more than 15 years. Belonging to a traditional metal workers family, Kamrool began his professional career making metal gates, railings and window grills for homes. For generations, his ancestors belonged to the metal smith community and were known to have made brass and copper utensils for the Mughal royal families. Moradabad is the metal center of the country and it is known for its production of brass and metal artifacts. Noah's Ark works with several artisans in and around Moradabad, who produce unique products that cater to both domestic and international markets.

Kamrool has a small workshop that provides sustainable income for 5 other artisans; each is engaged in the process of sorting, breaking and soldering the chains. Noah's Ark supported Kamrool in putting together a workshop for his metal work. The workshop has most of the required amenities except for the final finishing, which is carried out at another facility. Kamrool and his group of artisans are skilled in making beautiful picture frames, tea-light holders, bowls and other accessories with discarded bicycle chains. This collection is unique and gives a new meaning to discarded scrap metal.

The artisans require a sustainable supply of discarded bicycle chains to produce their work; usually these are sourced from the local scrap metal market. At times when the orders are large, they need to purchase the recycled chains from other cities, such as Delhi. Once the metal chains are acquired, they are sorted by size and straightened. Then they are sectioned according to the size or length required for a particular product. The sections of chain are placed on a metal frame or a dye, to insure consistency in the shape and size of each product, and soldered together. After the products are shaped, they are ready for a final finish; the metal is cleaned and rust and other impurities removed. The item is then polished or powder coated as required. Finally, the recycled chain products are ready to be sent to the warehouse for packaging and shipping.